What You’ll Need:

• Aussie Locker - Part#XD-13027

• 2 - Bottles of 85W-140 Gear Oil

• Axle Grease

• 13mm (12 Point), 13mm (6 point), 16mm (6 Point), 19mm, and 11/16" Sockets

• Ratchet

• Torque Wrench

• Breaker Bar

• Standard and 3 lb. Hammer

• Flat Chisel

• Pry Bar

• 3/16" Punch

• Bench Vice

• Floor Jack

• Jack Stands

• Wheel Chocks

• Zip Ties

• PB Blaster

• Oil Drain Pan

• Gasket Scraper

• Hi-Temp RTV

• Brake cleaner (spray can)

• Hand pump or funnel (for refilling diff when done)

Whats In The Box:

Heres The Locker Put Together:

The Install:

First Remove Wheels (19mm), Brake Calipers (13mm 6 Point), And Wheel Bearing Hub Bolts (13mm 12 Point) and Slid Axles out a little. The Do Not have to be completly removed for this. but i would remove them and clean the splines off befor reinstalling (there is a good chance that there is crap in your axle tubes).

Lossen the top most bolt most of the way, then remove all the other diff bolts. the top bolf will hold the cover on and prevent it from falling.

i used a painters hyde tool, but you could use a flat chisel to pry off the diff cover

remove top most bolt and lift the diff. cover out of the way

look! its a open dana 30 carrier!

i marked the top of both bearing cap retianers with a sctach awl

remove all bearing cap bolts and remember which side the bearing caps and bearing cap retainers belong to. (16mm 6 Point)

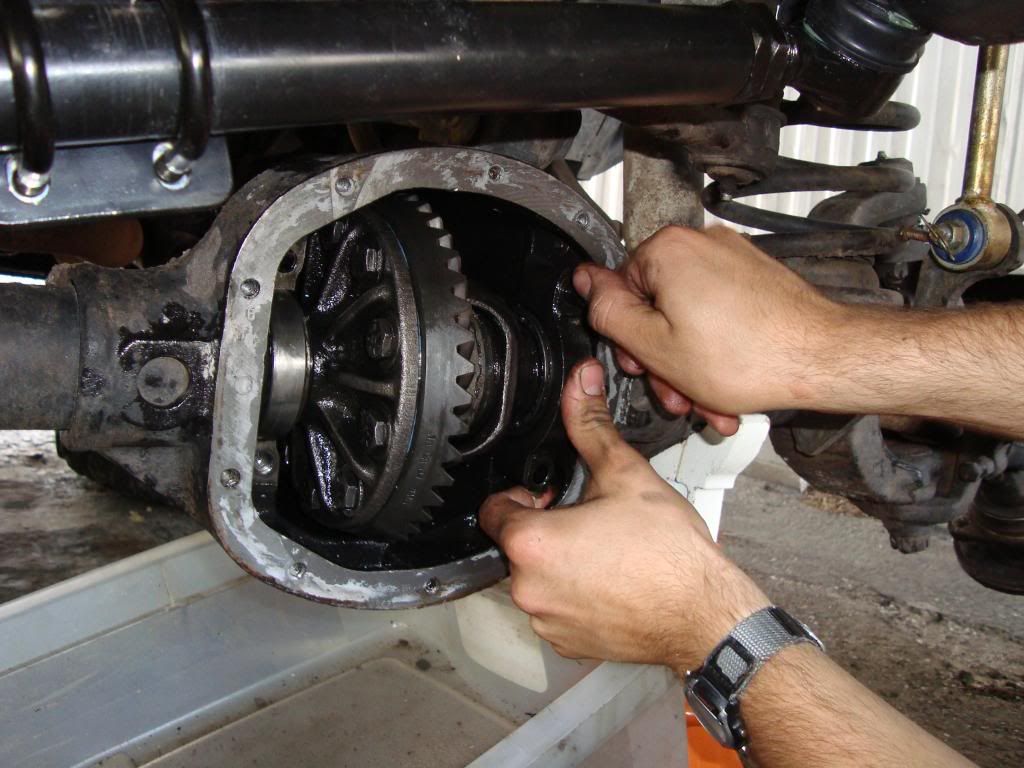

next using a pry bar and a hammer, gently pry out the carrier

once lose, you might have to disconnect the drivers side tie rod end of the steering linkage to remove the carrier (19mm 6 Point)

spider gears!

insert carrier into vise

clean and mark ring and carrier, so you know where it lines up

using a 11/16" 6 Point socket remove all bolts

break them!

remove them!

wow my shed is messy lol. i guess that happens when you work area is less than 10’x10’ lol.

also some of you might be like WTF? a drill?.. my answer to you is. my air ratchet broke ![]()

anyways, the ring gear will fall off

remove from vise and use a 3/16" punch to remove the rolling pin

next push out the pinion shaft

as per instructions, check the thickness of the shaft in the center using a dial caliper or micrometer, and where the spider gears were. if its out of spec. call up a buddy to drive your a$$ to a napa lol same thing if it fails the softness test.

Spin out the spider gears

same the thrust washers

and ziptie the spider gears and curved trust washers together, just in-case you need them again.

here come the fun part

remember that your not supposed to ingest the grease

but you need cover the locker side gears with it. the grease will act like glue holding the locker together while you install it.

grease the back as well and insert the thrust washer

insert into carrier and repeat with the other side

next insert the spacers over the hubs of the axle gears

insert pinion shaft, and measure with feeler gauges to make sure your in spec

if its in spec. remove spacers

grease up cam gear front and rear

insert spacer with flat part away from the ratchet end of the cam gear

insert into carrier

repeat the same for the other cam gear and spacer

grease up the 4 pins and insert them

grease up the 4 spring and insert them using a small flat head screw driver to help you

line up cam gears and spacers then install the pinion shaft

install rolling pin

back to the vise

line up your marker line

loc-tite!

install bolts in a criss-cross pattern and torque to 80 ft. LBS

scrap off all the old RTV you can. you want to do the best job possible. other wise you’ll be doing it again.

clean out you diff with a lint free rag… brake cleaner would of been awesome if i remembered to get some

put some grease on the bearing cap, and install to its respected side. remember that they have to go on the way they cam off

insert carrier into diff.

negotiate into place

i used loc-tite on the bearing cap bolts

put the bearing cap retainers back on the way they came off and torque to 45 ft. LBS

time to re install the axles, torque the wheel hub bolts to 75 ft. LBS, install the rotor & the brake calipers torque to 11 ft. LBS, and install the tires and lug nuts, torque to 95 ft. LBS.

preform the unlock test.

if it passes, clean diff cover and apply hi-temp RTV in a nice 1/4" bead all the way around. remember to move quick, you have less than 5 minutes

install all diff cover bolts in a criss-cross pattern and torque to 30 ft. LBS

fill her till she over flows with 85W-140 gear lube

then torque fill plug to 25 ft. LBS

lift her, remove jack stands, and lower her, and your done!

now you just have to wait for the 200 mile break in period.

Some Info Was Sourced From 4x4xplor.com/aussielocker.html