Let me just say this LJ has a great habit of throwing me totally unrelated problems in rapid succession in an effort to simply never be ready to use when I want it…

Back story:

Replaced the E-fan controller to eliminate wires and fuses melting with a 70A system.

Drove to Ricky’s to get my new gas tank installed.

ran for 20 minutes at 220F then surged to 250 in about 5 seconds.

Pulled over, didn’t shut it off, temp returned to 220 in about 1 minutes at idle.

Limped into Rickys with a surging IAC (2600 rpm) and shut it down. Steve and Mark took a look. Determined it was in fact bloody hot, but no puking of fluids.

They did the IAC and gas tank and also an oil seal that I can’t remember at that time.

Ricky drove it around after service, no overheat at that time.

I picked it up from him. Drove to the Jamestown bridge. It pegged like before just before the toll gate. I shut it down, ran the e-fan and tried to start. No start until it was below 210. then I got it home at 220-230.

At this point, I adjusted my e-fan controller to be sure it would come on at virtually any temp. It’s set to start at 150F and always run. Thought maybe the controlls had it shutting off at a high temp or something stupid.

Drove it locally on 4th of July. Same issue, but happens in as little as 10 minutes if I am at cruising (above 40mph).

So far attack plan:

changed t-stat

changed water pump

flushed system twice

vacuum draw to get coolant back in (to avoid air lock)

pressure test cylinders to try and see if there was a head gasket issue. All service done. No real change

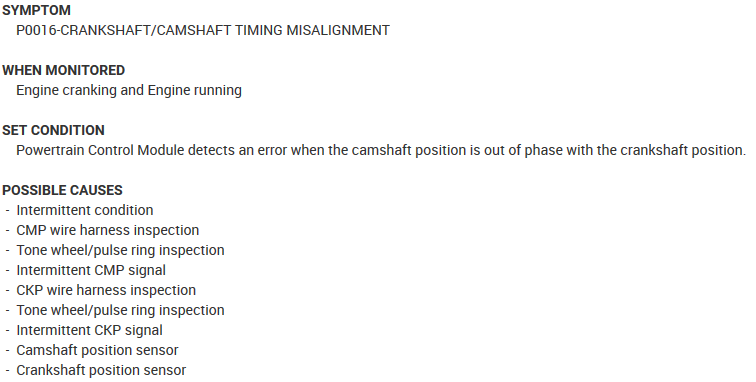

In the middle of all of this, I get a P0016 code. CPS is out of sync. Now I think Ricky did a seal on the distributor, but the sync is between the crank and the OPDA.

I look up OPDA issues… wall-paper worth of notes on the '05 OPDA failing, wearing the gears and going out of sync.

During all this, I buy a new muffler to change out my DYnomax V/T because it is recalled under warranty due to failing valves which cause it to flap and block exhaust flow (and make a racket).

Future plan A:

destroy this beat with C-4 and cry

Future plan B:

give up on the modified motor set-up and rob a bank so I can do a V8 swap and don’t Jeep for the next 5 years to save up for it.

Future plan C: (a.k.a. the rational one):

swap the OPDA with a modified crown Auto replacement with the bearing that allows oil flow

swap in the new muffle even though I don’t think it will fix the overheat

pressure wash the radiator and condenser in the grill to ensure air is flowing through and bugs/mud is not the killer here

test progress after each painful, time-consuming and expensive process.

If still no joy, consider replacing the radiator and/or e-fan under the assumption is has too much scale build to back flush out and/or the fan is losing CFM and can’t keep up to the highest demands.

I have not done a gas test where you can tell if exhaust gas is leaking into the coolant stream. I think that would conclude my finding to a head gasket or cracked head. I don’t want that to be the problem, but I am running out of ideas and a strategy to make progress on this fracking Jeep.

With all this story, does anyone have a novel idea on hi-speed overheat for a 05-06 TJ/LJ with an e-fan and aluminum radiator?

I was so happy Ricky solved my IAC issue and was hoping the racing of the IAC was somehow related to over heat. It’s not…

Any help on a strategy would be good. It’s with Jon Taggert locally here on the island for what was supposed to be a “failing waterpump is the root of all issues” diagnosis and fix. I need a plan now.